Today’s markets constantly test our trust in health labels, ingredient lists, and sustainability claims that shape what we buy. In the food industry especially, “eco-friendly packaging” has often become a form of environmental theater: gestures toward change without rethinking the system itself.

The truth is simple: we’ve been solving the wrong problem. Most companies ask, “How do we make plastic less harmful?” instead, “What if we didn’t need plastic at all?” From their base in India, Zerocircle is ushering a new age of truly circular materials – the kind that leave nothing behind. From regenerative pellets and coatings to flexible paper alternatives, the team is reimagining what sustainable packaging can be, and picking up global recognition along the way.

Their answer starts with what nature has already perfected. Seaweed has flourished on Earth for nearly a billion years — producing half of the planet’s oxygen, sheltering marine life, and nourishing life on land. It may also hold the key to fixing a broken system: seaweed contains the natural polymers we need, grows without soil, pesticides, or fresh water, restores ocean ecosystems as it grows, and it composts completely when we’re done with it.

We spoke with Zerocircle’s founder, Neha Jain about material innovation, the company’s R&D philosophy, and jumping into the deep unknown.

In a few sentences describe what you do at Zerocircle

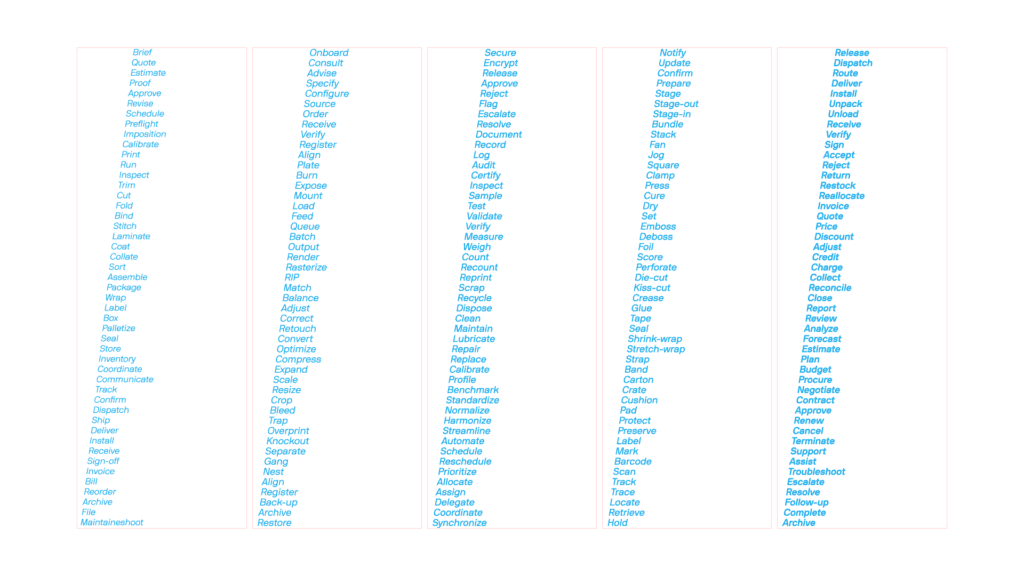

At Zerocircle we make seaweed-based alternatives to plastic that safely return to nature. We focus on single-use materials—especially those used with food—that are thrown away within minutes. Our goal is to build a new model for materials and systems that leave no harmful trace and help brands embrace an ocean-safe future.

Seaweed-based materials can serve a wide range of industries, from packaging and fashion to home goods and personal care. Could you share some examples of the products you’re working on — and what drives your focus on those particular applications?

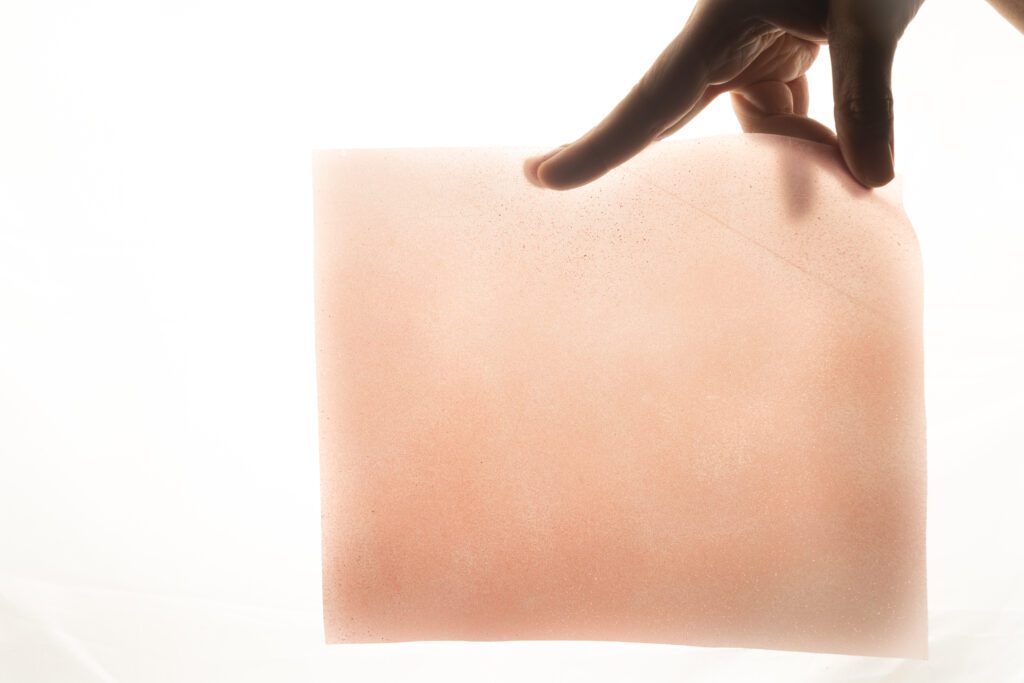

We are developing our seaweed-based solutions to replace hard-to-recycle plastics such as polystyrene and synthetic adhesives while addressing challenges like hydrophobic and barrier coatings through clean, safe chemistry. One key application in packaging is for takeaway food and beverages, which accounts for a significant share of single-use waste — from food boxes and ice cream cups to paper cups lined with plastic. We eliminate PFAs, also known as “forever chemicals”, valued for their heat resistance and durability but notorious for being toxic and environmentally persistent. Beyond packaging, our focus extends to solving larger environmental challenges. One of our most innovative breakthroughs is our tree-free paper made from Sargassum, a seaweed responsible for the world’s largest algal bloom in the Atlantic. Our seaweed paper is engineered for both performance and flexibility, making it ideal for conversion into high-barrier, visually refined packaging, from window boxes to mono cartons for fashion, cosmetics, and personal care.

Let’s talk supply chain: bringing technology to local production over sourcing through a global network of suppliers. On your site you mention that “Zerocircle’s technology is designed to create products in any coastal region, using locally sourced materials”. How does it work concretely? Can you take us behind-the-scenes of this approach?

Zerocircle’s model is designed to be grown locally and scaled globally. Since plastic is a global problem, our solution had to be both resource-scalable and technologically adaptable. Our patented technology enables seaweed-based materials to run on existing paper and plastic manufacturing lines without the need for new infrastructure or capital investment. This ensures that manufacturers anywhere in the world can produce sustainable alternatives using our materials and formulations. We source our seaweed primarily from coastal India, especially Tamil Nadu and Gujarat, and also from parts of Southeast Asia. As we scale, we are exploring partnerships with growers and processors across Asia and Africa to build a more resilient supply network.

To maintain environmental and quality standards, we work only with certified suppliers who follow sustainable harvesting and cultivation practices. Our partners use various techniques such as bamboo rafts, floating or rope cultures, stake and line systems, and net bags depending on the species and local ecology. Our model emphasizes local processing near cultivation sites, which reduces transport emissions and preserves the quality of raw material. The seaweed is processed into a refined feedstock at these coastal biorefineries, after which it is sent to us for quality testing and product formulation. This feedstock becomes the foundation for our innovations. It is transformed into coatings, pellets, films, seaweed paper, and finally into finished applications such as coated food boxes, wraps, and rigid packaging materials.

Can you tell me more about the team behind the company? And can you tell us more about what you love about it?

Our materials are developed by a passionate group of polymer chemists, engineers, and food technologists who push the limits of what seaweed-based innovation can achieve. They are the reason we can match, and often exceed, the performance of traditional plastics while staying true to our ocean-safe mission. Our commercial team who are sharp, curious, and very collaborative work closely with large brands and manufacturers to figure out how to make this transition possible within existing systems. It’s not just about selling a material, it’s about co-creating new models that make adoption easier and seamless.

And our marketing team is the creative engine that connects our work with the world. They lead our thought leadership initiatives, build external collaborations, and represent Zerocircle at key global events and trade shows. What I love most about this team is how multidisciplinary it is — scientists, chemists, engineers, techpreneurs, journalists and strategists. They always hit me with a statistical rundown of the situation, nudging me to read more and call for another round of discussions to play devil’s advocate on our positive findings. And all are working together towards a single vision: creating materials that keep plastic out of our oceans.

India’s vast coastline — over 7,500 km — offers huge potential for seaweed cultivation. How can we scale production in a way that protects delicate ecosystems and ensures long-term sustainability?

Scaling seaweed cultivation in a region like Asia and India is both an incredible opportunity and a responsibility. In India, we have the potential to build one of the world’s most vibrant seaweed economies, but it has to be done in a way that protects the very ecosystems that make it possible. At Zerocircle, we focus on working with native species that naturally belong to local waters. This ensures that cultivation supports biodiversity instead of disrupting it. Equally important is traceability, where we maintain clear visibility across our supply chain, right from the vendors we work with to the cultivation methods they use. We carefully vet our vendors and suppliers based on their adherence to sustainable cultivation practices, so that every part of the process aligns with our environmental standards.

Our partners use a variety of cultivation techniques suited to different regions and seaweed types. These include bamboo rafts, rope and floating raft cultures, stake or line systems, net bags, tube nets, and monoline setups. Each method is chosen based on local conditions such as tidal flow, water depth, and species characteristics. This flexibility allows us to scale responsibly while minimizing impact on marine habitats. What makes this model powerful is that it creates a balance between environmental, social, and economic outcomes. Seaweed farming not only absorbs carbon and supports marine life, but also provides livelihoods to coastal communities that have been affected by changing ocean conditions. By keeping sustainability at the core, we can grow this sector in a way that benefits both people and the planet.

Can you tell me more about the role of collaboration in moving your mission forward? Are there any ongoing or upcoming partnerships you’re particularly excited about?

Collaboration is absolutely central to what we do. Commercialising and scaling a new material that’s meant to replace something as resilient and persistent as plastic is no small task, and it cannot be done in isolation. It takes an entire ecosystem, from brands and converters to policymakers and end users, to build a system that supports this shift. We’ve been very encouraged by how the industry has responded. In our very first year, we partnered with Nestlé through their accelerator program, where we produced our first prototype. Today, we’ve built a strong commercial pipeline of over 50 direct buyers, including global manufacturers, paper converters, distributors, and major players in food and beverage, from aggregator platforms to large café and restaurant chains.

In 2025, we commercialised 150,000 food boxes coated with Zerocircle’s 100% home compostable, biodegradable coatings and are now scaling across regions including Asia, the EU, the USA, and the Middle East. Collaboration for us also extends beyond production. Sometimes, it’s about raising awareness and helping others feel part of the change. For example, we partnered with Zomato and Swiggy for a campaign that offered restaurant and café owners free samples of Zerocircle’s seaweed packaging. The response was incredible; we commercialised 100,000 food boxes through that initiative, with several restaurants becoming repeat customers.

So while collaboration is the foundation of our growth, it is also how we gather feedback from the market, validate our materials in real-world settings, and ensure they perform at scale for the businesses that use them. At the end of a deal, we want our partners to feel pride that they have adapted to a better model and are part of a new system that is actively choosing better.

Strategic investment — both public and private — is critical for pioneers like Zerocircle, whether it’s funding research, building infrastructure, or sharing technology. Where do we currently stand on government support and policy for seaweed innovation, and what would you like to see happen next?

Strategic investment and supportive policy are absolutely essential for this sector to grow. Right now, we’re seeing strong tailwinds. The EU’s new Packaging and Packaging Waste Regulation (PPWR) classifies PLA and PHA as plastics — strengthening Zerocircle’s position as a truly non-plastic alternative. At the same time, global single-use bans, PFAS restrictions, and EPR mandates are pushing brands toward safer, compostable materials. Broader frameworks like the EU Green Deal and Circular Economy Action Plan also prioritize plastic-free innovation. As marine and microplastic laws tighten, our microplastic-free materials are right in step with that shift.

That said, the road isn’t without hurdles. A lack of clear global definitions between natural polymers, bioplastics, and fossil plastics still causes confusion — and slows adoption. For a global company like ours, the lack of consistent international standards on plastics and their alternatives is a major gap. Consistent labeling and recognition will be key to reducing greenwashing and improving end-of-life recovery. Many “bioplastics” on the market still contain fossil inputs or shed microplastics as they degrade, and food-contact regulations remain fragmented and country-specific. Finally, unaligned biodegradability standards and trade barriers make scaling globally more complex than it needs to be.

And finally, what’s on your seaweed list? There are an estimated 10,000 to 12,000 species of seaweed, broadly grouped into red, green, and brown algae. Do you have any personal favorites?

It’s honestly hard to pick a favorite because all seaweeds are fascinating in their own way. When you see them underwater, they move so gracefully, almost like they’re breathing with the ocean. For centuries, seaweeds have been part of our lives through food, nutrition, and biofertilizers. What’s exciting now is how we’re discovering their potential to become the next generation of sustainable materials. Different seaweeds bring different strengths. Some of the red varieties are incredible for their natural gelling and film-forming abilities that work beautifully for coatings and flexible packaging. Brown seaweeds are known for their strength and elasticity, useful for materials that need durability and stretch. And then there are species that have natural adhesive qualities, which is fascinating for us as we explore bio-based alternatives to synthetic binders.

What makes seaweed remarkable is not just its chemistry, but its simplicity. It grows in saltwater, needs no arable land, no freshwater, and no fertilizers, while quietly capturing carbon and restoring marine balance. Every species has its own little superpower, and together they remind us that the answers to some of our biggest environmental challenges might already be floating in our oceans.