Across most organizations, print and packaging sit at an odd intersection. They touch supply chain, marketing, operations, and compliance, but they don’t clearly belong to any one system or team. Work gets done, orders ship, and problems are handled as they come up — often without much expectation that decisions will need to be revisited later.

At the same time, many organizations are trying to bring more structure and visibility to how work moves across their supply chains. Inventory, transportation, and fulfillment are increasingly managed through shared systems that make it easier to see what’s happening, spot issues early, and coordinate across teams.

Print and packaging have largely been managed differently.

Why Print Sits Outside Most Control-Tower Views

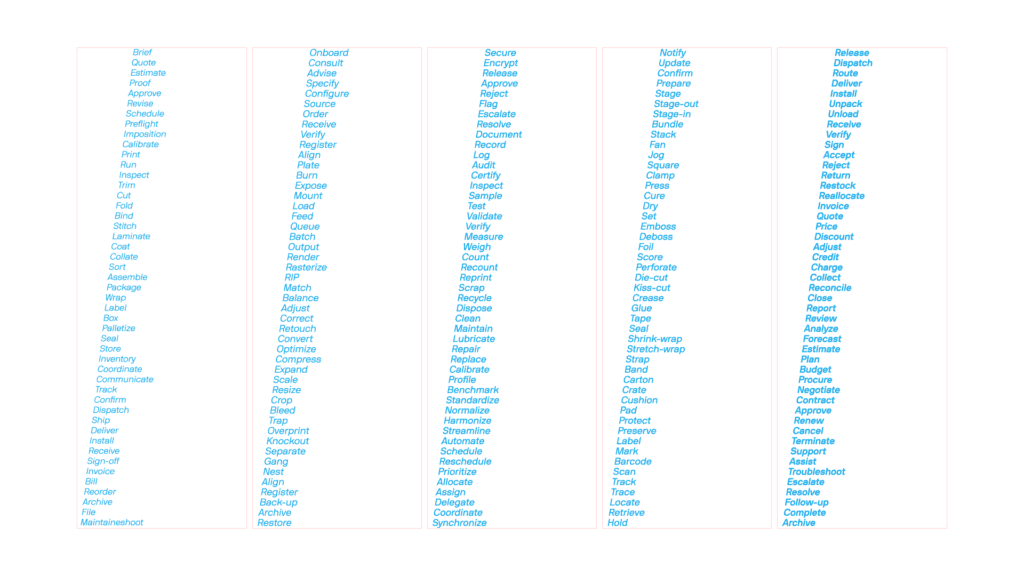

Print is not a single function or workflow. It spans commercial print, packaging, labels, inserts, kits, and branded merchandise — and, in many cases, packaging as well — much of which is sourced and manufactured overseas and involves its own materials, components, and distribution paths. These programs are often managed by different internal teams, sourced through different suppliers, and produced on different timelines.

Historically, print has been treated as work with a clear start and end. A request is made, a job is produced, and once it ships, the work is considered complete. Success is measured by cost, quality, and timing for that specific order, not by whether decisions or data will need to be referenced later.

That framing made sense when print was evaluated primarily as an execution task rather than an information domain.

As a result, the details that shape print programs — specifications, material choices, component decisions, revisions, substitutions, and shipping instructions — are typically distributed across emails, files, vendor portals, and individual experience. Continuity exists, but it lives with people rather than inside shared infrastructure.

As a result, print has rarely been set up to carry its own history forward in a consistent, system-level way.

How Control-Tower Frameworks Define Visibility

Gartner describes control-tower approaches as a way to achieve end-to-end visibility across multiple supply-chain domains, allowing organizations to detect issues early and coordinate responses across teams.

A core assumption in this model is domain-specific visibility. Control-tower approaches do not replace the systems that manage individual functions. They depend on those systems to provide clean, consistent information that can be pulled together and reviewed at a higher level.

Those functions are typically managed through systems such as ERP platforms, transportation management systems, warehouse management systems, and planning tools — all of which generate structured data as part of day-to-day operations.

For this approach to work, each domain needs to be able to answer a basic set of questions reliably:

- What was produced?

- To what specification?

- In what quantity?

- Where did it go?

- Under what requirements or conditions?

These are the same questions organizations expect to answer in any operational domain. Print is not unusual in the questions it raises — it is unusual in how hard those answers are to retrieve.

Accountability Is Expanding Beyond Production

Emerging sustainability and reporting requirements are changing what organizations need from print and packaging.

Extended Producer Responsibility (EPR) regulations and other materials-based reporting obligations require brands to account for what they place into the market — not just finished items, but the materials and components that make them up, the quantities produced at each level, and the jurisdictions into which those materials are shipped.

This information already exists across the print and packaging ecosystem, but it is rarely captured in a consistent way that can be carried forward. Retrieving it often depends on institutional memory, manual follow-ups, and vendor-by-vendor clarification, especially as internal roles change.

In practice, this reconstruction work falls to the brand. Information has to be pulled from suppliers, reconciled across formats, and organized into a coherent reporting response — often under time pressure and without a shared system to rely on.

A Parallel from Financial Reporting

A similar shift played out over time in U.S. public-company reporting. Financial disclosure moved from paper filings to electronic submission, and later to structured formats designed to make data cleaner, more comparable, and easier to analyze. Each step increased transparency, but also increased the amount of information companies were expected to manage and stand behind.

When structured reporting formats such as XBRL were introduced under the U.S. Securities and Exchange Commission, reporting changed from a largely automated output of an approved document into a separate, time-consuming process that required additional work and careful verification.

The introduction of modern reporting platforms — most notably Workiva — addressed that shift by treating reporting as an information problem rather than an added production task. The opportunity existed because the incumbent, production-led model was not designed to meet the new requirement, and extending it through manual steps proved unsustainable as expectations increased.

The Visibility Question for Print

As organizations mature their control-tower approaches, print and packaging present a practical challenge.

These frameworks rely on domains being able to describe their activity in consistent, retrievable terms. They cannot infer what they are not given. If specifications, material data, component details, and shipping context are not retained in a usable form, print remains opaque — even as expectations for accountability increase.

This is not a failure of printers, brokers, or managed print services. These operating models were built to get work produced and delivered, not to function as long-term systems of record.

But as reporting, sustainability, and cross-functional coordination become standard operating requirements, that distinction matters.

What It Means Going Forward

Print and packaging will always involve physical production, lead times, and real-world limits that software cannot eliminate. They are unlikely to behave like real-time digital domains.

What is changing is the expectation that print be legible — meaning specifications, materials, components, quantities, and distribution decisions can be retrieved, understood, and reconciled over time, rather than reconstructed after the fact.

What is becoming clear is that, as organizations scale, print cannot indefinitely sit outside the systems they rely on to understand how they operate.