Editor’s Note

This article is not intended to recommend a specific print model or suggest that one approach is inherently better than another. Printers, brokers, and managed print services each represent a distinct way of organizing responsibility for print and packaging work.

The goal is to describe how these models differ in practice — particularly in how decisions are made, how work is coordinated, and how information is retained over time. Those differences matter more today as reporting, compliance, and accountability expectations increase, and as responsibility for print often sits alongside many other operational priorities.

Introduction

Print and packaging are typically managed as an indirect operating category. Responsibility often sits within operations, supply chain, procurement, or a shared services function — alongside many other priorities.

There are a few established ways organizations structure that responsibility. Some work directly with printers. Others rely on intermediaries to coordinate production. Larger organizations may place portions of their print programs under managed print services agreements. Each model reflects a different trade-off between control, delegation, cost, and continuity.

The distinctions between these models are easy to overlook because, on the surface, they all deliver printed output. Where they differ is in how decisions are made, how changes are handled over time, and where information about specifications, materials, and production history actually lives.

Those differences are becoming more consequential as brands face greater expectations around reporting, compliance, and repeatability — often across multiple products, suppliers, and jurisdictions.

Printer-Led Models

Manufacturing is the foundation of the entire print ecosystem, because every print job ultimately ends with a printer.

In a printer-led model, a brand works directly with a manufacturing partner to produce printed materials. The relationship is typically transactional and job-based, shaped by the printer’s equipment, location, and production strengths.

Printers are highly focused on print production. Their role is to take a specification, run it efficiently on the equipment they own, and deliver finished materials out of their facility. Decisions about where a product will ultimately ship, how far it will travel, or whether another production approach might make more sense at a different volume are usually outside that scope.

This model works well when needs are consistent and conditions are stable. A capable printer can execute reliably, respond quickly, and solve problems within the context of their operation.

Over time, strain can appear when conditions change. Volumes shift. Distribution moves to a different region. A job that once made sense on a specific press may need to be produced using a different process or closer to where it will be used.

At that point, the challenge for the brand is less about producing the work and more about carrying context forward — understanding what was done previously, why it was done that way, and how those decisions should adapt.

Broker-Led Models

In a broker-led model, a brand works with an intermediary who coordinates print production through a set of trusted manufacturing partners.

Brokers do not own production equipment. Their value comes from experience, relationships, and familiarity with how different printers operate. Over time, many brokers develop a small network of reliable suppliers across specific categories, formats, or regions.

For brands, this model is often appealing because it offloads coordination. Rather than managing multiple printers directly, the brand relies on the broker to act as an agent — handling back-and-forth, comparing options, and keeping work moving without requiring deep involvement from internal teams.

A broker who knows a program well can provide continuity from job to job. At the same time, because the model relies on personal knowledge rather than shared systems, context around specifications, revisions, and past decisions lives outside any central place. When a broker, a vendor, or a brand contact changes, that context has to be rebuilt, because it isn’t consistently organized or recorded in a form that can be carried forward.

Managed Print Services

In a managed print services model, a brand enters into a contractual arrangement that places some or all of its print SKUs under the control of a single service provider.

The managed print service does not typically own manufacturing equipment. Instead, it operates through a network of printers and suppliers, assuming authority for how work is specified, sourced, and produced. Decisions about specifications, formats, vendor selection, production routing, and repeat ordering are determined by the managed print service, not by individual brand teams or prior vendor relationships.

These arrangements are usually tied to explicit savings commitments. Print is treated as a managed spend category, and the service provider is accountable for meeting cost targets across the program. How those targets are achieved — including changes in suppliers, locations, or production approaches — is generally left to the provider’s discretion.

Many managed print services describe technology platforms that support reporting on spend, service levels, and contract performance. From a brand perspective, these tools are oriented toward oversight of the service relationship rather than day-to-day visibility into individual projects and production decisions.

In this model, print is centrally controlled. Visibility into how and why specifications change over time depends on what is explicitly shared by the service provider, rather than on a shared operational system accessible to brand teams.

The Emerging Pressure

Print has always required coordination. What’s changing is the expectation that decisions can be revisited, explained, and reported on over time.

Sustainability and materials reporting requirements already exist in some jurisdictions and are expanding. Extended Producer Responsibility is one example, but it is not the only one. Increasingly, brands are being asked to account for what they place into market — by material type, weight, quantity, and jurisdiction.

To do that, brands have to go back to their printers and packaging suppliers for product data, and to their logistics and fulfillment partners for shipping and distribution information. Knowing what was produced is only part of the picture. Understanding where those materials ultimately went is equally important.

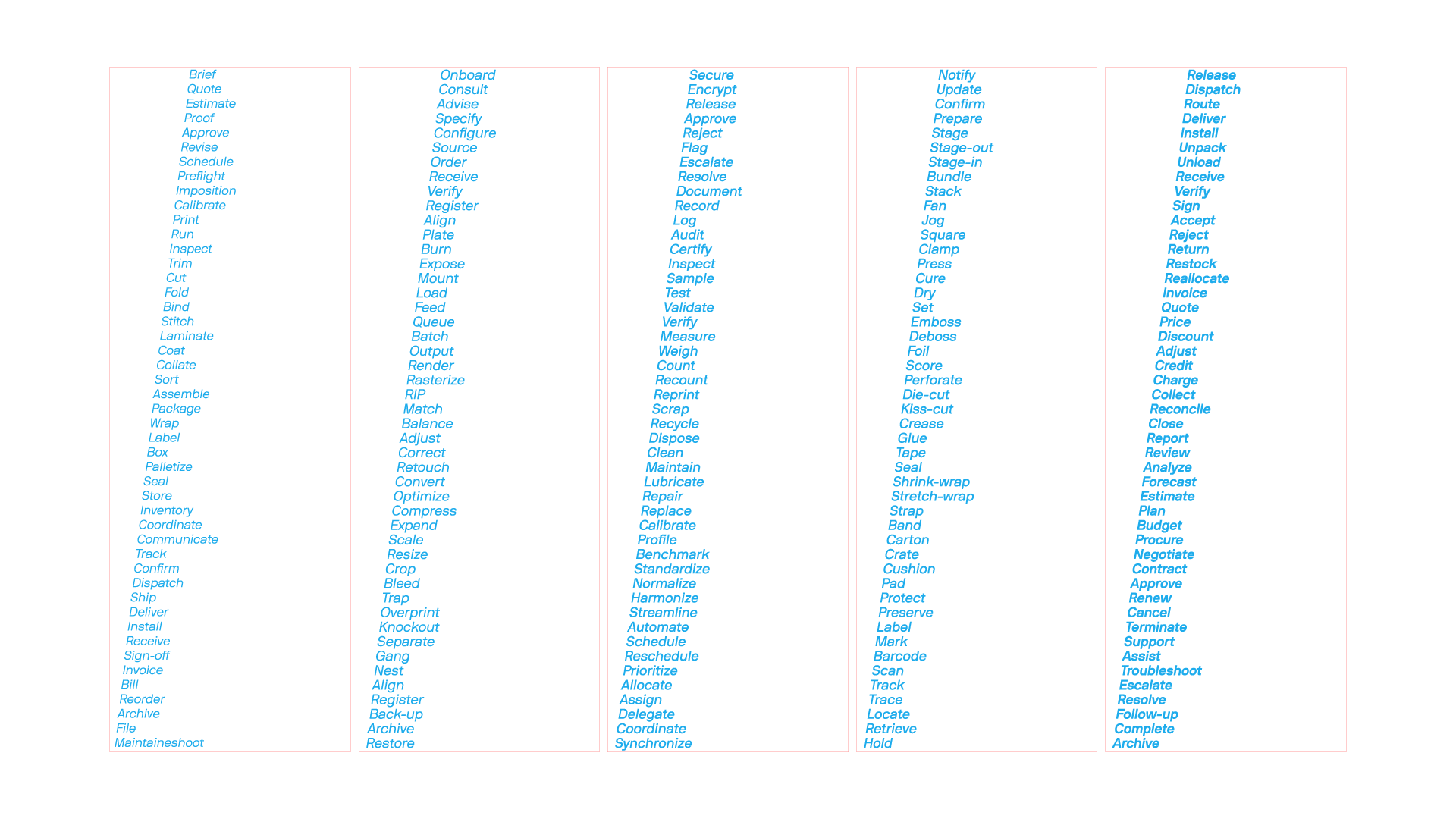

Meeting these requirements depends on details that are often spread across systems and partners: substrates, coatings, adhesives, component weights, production volumes, shipment destinations, and timing. Bringing that information together requires more than summary totals; it requires being able to trace and compare decisions across programs and over time.

Other segments of print have faced similar shifts. In financial printing, regulatory changes introduced by the U.S. Securities and Exchange Commission required firms to move from paper-based disclosure to structured digital reporting. Large, well-capitalized financial printers were able to invest in the systems and processes needed to support those requirements. Much of the print and packaging industry is far more fragmented, making this kind of adaptation uneven.

As reporting expectations increase, brands will need deeper collaboration with their manufacturing and logistics partners. Whether that collaboration is manageable depends on how well specifications, materials, and distribution decisions are retained and accessible over time.