Protecting a product doesn’t stop at the box. By the time it lands at your doorstep, it’s been lifted, moved, and kept in motion by countless invisible hands. In an ever-connected world relying heavily on muscular supply chains, it’s no secret that humans and robots are working side by side, as trucks rumble and air routes fill with more than 60 million packages crossing the U.S. every single day.

One energetic company is stepping back to consider this interconnected system spanning people, automation, and goods from a bird’s-eye view. By focusing on everyday paper-based materials, such as bubble wrap, crinkled shred, and air pillows, Sustnbl wants to make it easier for more businesses to make the switch while meeting the needs of those who lift heavy objects on warehouse floors. Excessive lifting can quickly cause back injuries, and wearable technologies like exosuits improve worker safety by reducing the stress of repeated motion on the body. Sustnbl founder Lev Girshfeld shares his candid views on sustainability and greenwashing, viral marketing ideas, and the overlooked details that keep packaging operations running smoothly.

In a few sentences, how would you describe what you do at Sustnbl?

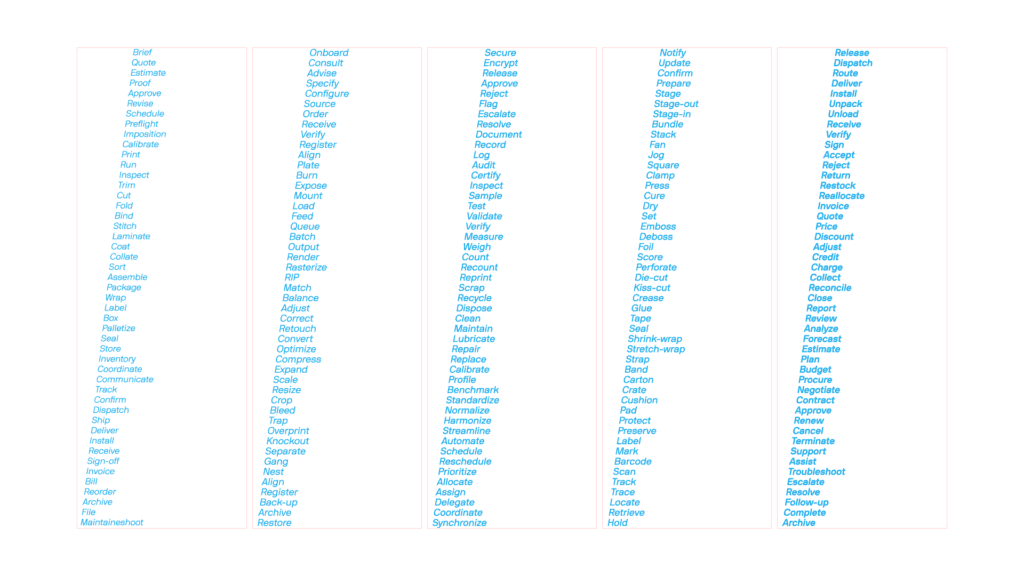

At its core, we place ourselves as a sustainability solutions provider. Packaging is our primary focus, everything inside the box, outside the box, and even beyond the pallet. We specialize in paper-based, bio-based, and PCR materials. So when a brand comes to us looking to lower CO₂ emissions or eliminate plastic, we help them find a more sustainable alternative that still protects the product.

I am curious about your offer. You describe Sustnbl as a holistic system. Beyond greener packaging, you also pay attention to workforce efficiency. How do these areas align?

I’m glad you picked up on that. Protecting a product isn’t just about the box—it’s also about how people interact with it. Take a warehouse with 100 packers, all using the same packaging material. Even if we introduce a sustainable option—say, paper air pillows or paper bubble wrap—the way those workers handle the material directly affects how the product arrives to the customer. Packing is physically demanding work. Someone lifting boxes for eight hours a day is going to feel it. That’s where workforce solutions come in. We offer exosuits, wearable technology that reduces physical strain by about 50%. If workers feel better at the end of the day, they make fewer mistakes, there’s less injury, and the overall operation runs more smoothly. Sustainability isn’t just materials. It’s people, process, and product working together.

Right now we’re seeing a huge spike in humanoid robots. Do you think robots will replace humans in packaging any time soon?

There are definitely applications where robots make sense. But I don’t believe they’ll fully replace humans, at least not yet. Not every company has the space, infrastructure, or capital for automation, and robots still lack the dexterity humans have. I saw this firsthand at a facility with six packing stations run by people, right next to six robotic stations. The humans packed faster, by a lot. A task that took them 45 seconds took the robot three minutes. Why? The packers had done it thousands of times. They knew exactly how to move around the pallet. Machines operate within parameters someone programs. Humans adapt instinctively. They see more than we give them credit for.

You’re open to working with everyone from small shops to large-scale operations. What changes when you’re supporting a brand shipping 50 orders versus 50,000?

Our approach doesn’t really change in terms of care or problem-solving. We always focus on finding the best solution for the application, regardless of size. What does change is the backend. Larger operations need more ongoing maintenance and support. When you’re shipping 2,000 orders a day, every day, equipment uptime matters. But the core conversation is the same: “This is what we’re using now. We want to make a change. Will this work with our product?”

Sustainable options are often perceived as more expensive.

How do you address that hesitation?

We position sustainability as a decision change, and change is expensive. If you switch materials, you might need new equipment. You might need to retrain packers. But what you gain is often overlooked. Packaging becomes a marketing touchpoint. When someone opens the box and sees thoughtful, sustainable materials, there’s an emotional response: “I love this brand. They care.” That translates into loyalty, word of mouth, and often a higher company valuation. Yes, paper can cost more upfront. But what are you getting in return? Less spend on marketing. More brand equity. A bigger market share.

How competitive is the paper-based packaging distribution space?

There are a few distributors in the US with similar sustainability goals, but many focus heavily on custom materials. Our focus is different. We concentrate on day-to-day consumables, bubble wrap, void fill, the materials used at scale, every single day. The void fill and bubble wrap market alone is a billion-dollar industry. Our thinking is: if we can change the everyday materials, we can make the biggest impact. Custom solutions can come later.

Your branding feels like a clear break from traditional companies in the packaging business. Was that intentional?

Absolutely. The new generation of purchasers lives on their phones. You have about eight seconds to make an impression. When people see our products, there’s often an aha moment, “I’ve never seen this before.” That reaction matters. People feel good about the decision they’re making. They feel good about the material, the brand, and the impact.

Can you recall a moment when this sentiment really came to life in concrete situations?

Yes, at Pack Expo in Chicago. It’s a very corporate environment. Suits, handshakes, the whole thing. We got a tiny booth and on the back of it we put a big sign that said: “Fuck plastic.” We were trying to be bold and have fun. And the reactions told us everything. Big companies stopped by and remembered us. That’s when we knew: we’re onto something.

Looking ahead, what innovations in materials or logistics excite you most?

I’ve always been fascinated by mushroom-based packaging—mycelium. I think it has huge potential, especially for luxury brands that need molded, high-end presentation. Many of these companies are Europe-based right now, mainly because production infrastructure is still developing. Another company we work with is Releaf. They make paper from fallen leaves. It’s an incredible concept. They’re based in France, originally Ukrainian, and I think they’d do incredibly well in the US. We have leaves everywhere—entire systems built just to blow them away.

Finally, what’s the biggest misconception brands have about sustainable packaging?

People often compare plastic and paper directly, expecting similar cost and performance. But it’s really apples to oranges. They have different material properties, different use cases, and different impacts. Paper may sometimes be more expensive, but it’s often more impactful. There’s also a lack of understanding around how paper and plant-based materials are made and where they come from. Plastic feels abundant. Paper feels abundant too, but that doesn’t mean it’s everywhere.